The general copper wire safety calculation method is:

The safe current-carrying capacity of 2.5 square millimeter copper power cord-28A.

The safe current-carrying capacity of the 4 square millimeter copper power cord-35A.

The safe current carrying capacity of 6 square millimeter copper power cord-48A.

The safe current carrying capacity of 10 square millimeter copper power cord-65A.

The safe current carrying capacity of the 16 square millimeter copper power cord-91A.

The safe current carrying capacity of 25 square millimeter copper power cord-120A.

If it is aluminum wire, the wire diameter should be 1.5-2 times that of copper wire.

If the copper wire current is less than 28A, it is safe to use 10A per square millimeter.

If the copper wire current is greater than 120A, take 5A per square millimeter.

The current that the cross-sectional area of the wire can pass normally can be selected according to the total number of currents it needs to conduct, and it can generally be determined as follows:

Ten under five, one hundred on two, two, five, three, five, four, three realms, seventeen five and two and a half times, the copper wire upgrade count.

To explain it to you, it is an aluminum wire that is less than 10 square, and the square millimeter is multiplied by 5. If it is copper wire, it will be raised by one level, such as 2.5 square copper wire, it will be calculated by 4 square. They are all cross-sectional area multiplied by 2, 25 squares or less multiplied by 4, 35 squares or more multiplied by 3, seven and 95 squares are multiplied by 2.5, these few formulas should be easy to remember,

Explanation: It can only be used as an estimate, not very accurate.

In addition, if you remember the copper wire of less than 6 square millimeters in the room, it is safe that the current per square does not exceed 10A. From this perspective, you can choose 1.5 square copper wire or 2.5 square aluminum wire.

Within 10 meters, the wire current density is 6A/mm2, 10-50 meters, 3A/mm2, 50-200 meters, 2A/mm2, and less than 1A/mm2 above 500 meters. From this perspective, if it is not very far away, you can choose 4 square copper wire or 6 square aluminum wire.

If the power supply is really 150 meters away (not to mention whether it is a tall building), 4 square copper wires must be used.

The impedance of a wire is directly proportional to its length and inversely proportional to its wire diameter. Please pay special attention to the wire material and diameter of the input and output wires when using the power supply. To prevent accidents caused by overheating of the wires due to excessive current.

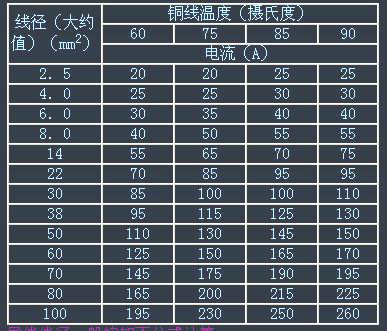

The following is a table of the wire diameter and the maximum current that the copper wire can withstand at different temperatures.

The wire diameter is generally calculated according to the following formula:

Copper wire: S= IL / 54.4*U`

Aluminum wire: S= IL / 34*U`

In the formula: I——the maximum current passing through the wire (A)

L-the length of the wire (M)

U`——allowable power drop (V)

S——The cross-sectional area of the wire (mm2)

Description:

1. U` voltage drop can be selected by considering the range of equipment (such as detectors) used in the entire system to the power supply voltage rating of the system.

2. Lean up the calculated cross-sectional area.

Estimation of current carrying capacity of insulated wires

The relationship between current-carrying capacity and cross-section of aluminum core insulated conductor

导线截面(mm²) | 1 | 1.5 | 2.5 | 4 | 6 | 10 | 16 | 25 | 35 | 50 | 70 | 95 | 120 |

载流是截面倍数 | 9 | 9 | 9 | 8 | 7 | 6 | 5 | 4 | 3.5 | 3 | 3 | 2.5 | 2.5 |

载流量(A) | 9 | 14 | 23 | 32 | 42 | 60 | 90 | 100 | 123 | 150 | 210 | 238 | 300 |

Estimation formula: multiply by nine at 2.5 and go up and minus one. Thirty-five times three and five, and both groups minus five. The conditions are changed and the conversion is added, and the high temperature 10% copper upgrade. The number of piercing pipes is two, three, four, and eight or seventy-six percent full load current.

Description:

(1) The formula in this section does not directly indicate the current carrying capacity (safe current) of various insulated wires (rubber and plastic insulated wires), but "cross-section multiplied by a certain multiple", which is obtained through mental calculation. It can be seen from the table that the multiple decreases with the increase of the cross section.

(2) "Two-and-a-half five times down by nine, going up and down by one" refers to various cross-section aluminum core insulated wires of 2.5mm2 and below, and its current-carrying capacity is about 9 times the number of cross-sections. Such as 2.5mm2 wire, the current carrying capacity is 2.5 × 9 = 22.5 (A). The multiple relationship between the current-carrying capacity of 4mm2 and above conductors and the number of cross-sections is to line up along the wire number, and the multiples are successively reduced by 1, namely 4×8, 6×7, 10×6, 16×5, 25×4.

(3) "Thirty-five times 3.5, doubles in groups minus five" means that the current carrying capacity of a 35mm2 wire is 3.5 times the number of cross-sections, that is, 35×3.5=122.5(A) . From the wire of 50mm2 and above, the multiple relationship between the current-carrying capacity and the number of cross-sections becomes a group of two wire numbers, and the multiples are successively reduced by 0.5. That is, the current carrying capacity of 50 and 70mm2 wires is 3 times the number of cross sections; the current carrying capacity of 95 and 120mm2 wires is 2.5 times the number of cross-sectional areas, and so on.

(4) "Conditions have changed, plus conversion, high temperature 10% copper upgrade". The above formula is determined by the aluminum core insulated wire and the open coating at an ambient temperature of 25°C. If the aluminum core insulated wire is exposed to the area where the ambient temperature is higher than 25℃ for a long time, the current carrying capacity of the wire can be calculated according to the above formula calculation method, and then a 10% discount is enough; when the copper core insulated wire is not used, Its current-carrying capacity is slightly larger than that of the aluminum wire of the same specification. According to the above formula method, the current-carrying capacity of one wire larger than the aluminum wire can be calculated. For example, the current carrying capacity of 16mm2 copper wire can be calculated as 25mm2 aluminum wire.

Copyright © Hubei Hongle Cable Co., Ltd

Record No:鄂ICP备19017660号 Technical support:![]() onnuoIAD

onnuoIAD