The use of power cables has a history of more than 100 years. In 1879, American inventor T.A. Edison wrapped jute on a copper rod and threaded it into an iron pipe, and then filled it with asphalt mixture to make a cable. He laid this cable in New York and pioneered underground power transmission. The following year, the British Callender invented pitch-impregnated paper insulated power cables. In 1889, the British S.Z. Ferranti laid a 10 kV oil-impregnated paper insulated cable between London and Dartford. In 1908, Britain built a 20 kV cable network. Power cables are used more and more widely. In 1911, Germany started the development of high-voltage cables by laying 60 kV high-voltage cables. In 1913, the German M. Horchstedt developed a component phase shielded cable, which improved the electric field distribution inside the cable and eliminated the tangent stress on the insulating surface, which became a milestone in the development of power cables. In 1952, Sweden laid 380 kV ultra-high voltage cables in the northern power plant, realizing the application of ultra-high voltage cables. By the 1980s, 1100 kV and 1200 kV UHV power cables had been made.

2020-09-14

Aluminum alloy power cable is a new type of material power cable with AA8030 series aluminum alloy material as the conductor, and adopts special roll forming wire stranding production technology and annealing treatment. Alloy power cables make up for the shortcomings of pure aluminum cables in the past. Although the electrical conductivity of the cable is not improved, the bending performance, creep resistance and corrosion resistance are greatly improved, which can ensure that the cable remains continuous during long-term overload and overheating. The performance is stable. The use of AA8030 series aluminum alloy conductors can greatly improve the conductivity and high temperature resistance of the aluminum alloy cable, while solving the problems of pure aluminum conductors and creep. The electrical conductivity of aluminum alloy is 61.8% of the most commonly used benchmark material copper IACS, and the current carrying capacity is 79% of copper, which is better than the pure aluminum standard. But under the same volume, the actual weight of aluminum alloy is about one-third of copper. Therefore, the weight of the aluminum alloy cable is about half of the copper cable at the same current carrying capacity. Using aluminum alloy cables to replace copper cables can reduce cable weight, reduce installation costs, reduce equipment and cable wear, and make installation easier.

2020-09-14

Aluminum alloy cables have been developed and used in the United States in 1968 for 52 years. The product has been widely used, and the market share of North American countries has reached 80%. After 52 years of practice, it is safe to use aluminum alloy cables without any failure.

2020-09-14

The good mechanical and electrical properties of aluminum alloy power cable make it widely used in various fields of the national economy, such as ordinary houses, high-rise buildings, elevators, large and small supermarkets, subways, airports, stations, hospitals, banks , Office buildings, hotels, postal and telecommunications buildings, exhibition halls, libraries, museums, ancient buildings, schools, power buildings, public entertainment venues, tunnels, underground buildings, warehouses, etc., can also be used in metallurgy, steel, coke, coal, Power plants, power transmission and substations, shipbuilding, petroleum, chemical, pharmaceutical, nuclear power plants, aerospace, military, papermaking and other industries, as well as household appliances, automobiles, and public transportation facilities.

2020-09-14

The corrosion resistance of pure aluminum is better than that of copper, but the corrosion resistance of aluminum alloy is better than that of pure aluminum, because the rare earth and other chemical elements added to aluminum alloy can increase the corrosion resistance of aluminum alloy, especially the electrochemical corrosion resistance. The long-term electrochemical corrosion problem of pure aluminum at the joint is solved.

2020-09-14

Solar energy technology will become one of the green energy technologies in the future. Solar energy or photovoltaic (PV) is widely used in China. In addition to the rapid development of government-supported photovoltaic power plants, private investors are also actively building plants and plan to put them into production for global sales. Solar modules.

2020-09-14

The control cable is a PVC insulated and PVC sheathed control cable suitable for use in industrial and mining enterprises, energy and transportation departments, and for control and protection of lines with AC rated voltages below 450/750 volts.

2020-09-14

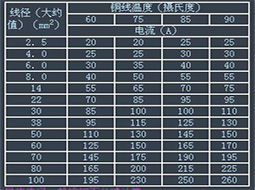

The general copper wire safety calculation method is:

The safe current-carrying capacity of 2.5 square millimeter copper power cord-28A.

The safe current-carrying capacity of the 4 square millimeter copper power cord-35A.

The safe current carrying capacity of 6 square millimeter copper power cord-48A.

The safe current carrying capacity of 10 square millimeter copper power cord-65A.

The safe current carrying capacity of the 16 square millimeter copper power cord-91A.

The safe current carrying capacity of 25 square millimeter copper power cord-120A.

If it is aluminum wire, the wire diameter should be 1.5-2 times that of copper wire.

If the copper wire current is less than 28A, it is safe to use 10A per square millimeter.

If the copper wire current is greater than 120A, take 5A per square millimeter.

Mineral insulated cable (Mineral insulated cable) is a kind of cable in which a copper conductor core is wrapped with a copper sheath, and magnesium oxide powder is used as an inorganic insulating material to isolate the conductor and the sheath. The outermost layer can be appropriately selected as required. Commonly known as MICC or MI cable. There is a similar cable that uses metal instead of copper sheath to wrap the core wire and insulating material, which is called Mineral insulated metal sheathed cable (MIMS Cable).

2020-09-14Copyright © Hubei Hongle Cable Co., Ltd

Record No:鄂ICP备19017660号 Technical support:![]() onnuoIAD

onnuoIAD